Source high-quality raw materials, such as yarns or fibers, for the weaving process.

Utilize modern weaving looms and equipment to manufacture fabrics according to design specifications.

Monitor and control the weaving process to ensure consistency and quality.

Treat fabrics with various chemical processes to achieve desired characteristics (e.g., color, texture, or durability).

Implement dyeing or printing processes to add color or patterns to the fabrics.

Conduct quality checks at each processing stage to maintain product standards.

Apply finishing treatments to enhance fabric properties, such as softness, sheen, or water resistance.

Inspect fabrics for any defects or inconsistencies before proceeding to the next stage.

Ensure that finished fabrics meet customer specifications and quality standards.

Prepare patterns for cutting fabrics based on approved designs.

Use cutting machines to precisely cut fabric panels according to the patterns.

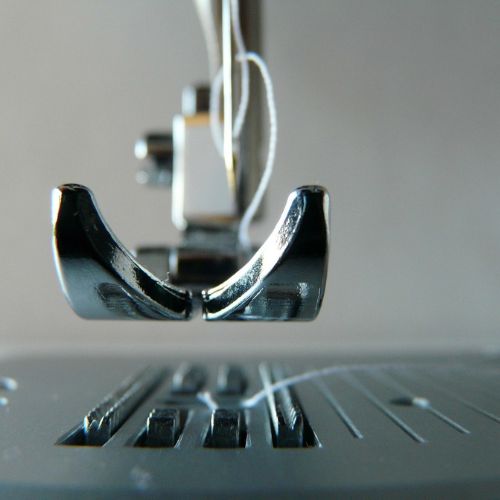

Assemble cut fabric pieces into final products through sewing and other production processes.

Conduct a thorough inspection of finished products to ensure they meet quality standards.

Address any defects or issues identified during the inspection process.

Implement quality control measures to uphold the company’s reputation for excellence.

Package finished products securely to prevent damage during transportation.

Label packages with relevant product information, including care instructions.

Ensure compliance with packaging regulations and standards.